Summer is here, and as we begin to crank up the AC, it is important to remember that your electronic parts and products could be in danger as well, especially if they operate (or are left) in extremely hot or extremely cold environments. Just imagine what would happen to a phone left inside a car in Phoenix or Palm Desert during a heat wave!

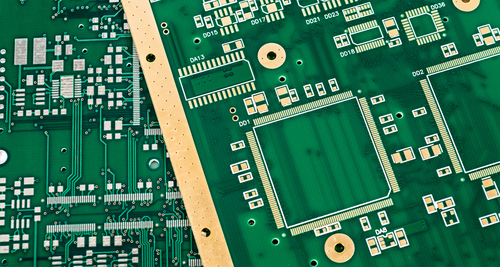

One of the most effective ways to protect your printed circuit boards is to apply conformal coating. This thin film can insulate your circuit boards from external heat and even the heat that your product produces as it runs. At Yun Industrial ACME PCB Assembly, we offer a variety of conformal coating services to our clients.

CONFORMAL COATING TYPES

CONFORMAL COATING TYPES

There are a number of options for coating technologies, and the best option should depend mainly on the protection required. Application method and ease of rework are also important factors, but should generally be considered secondary to the protective performance needed.

Traditional Conformal Coatings

What we are calling “traditional” conformal coatings are 1-part systems that have a resin base, and may be diluted with either solvent or (in rare cases) water. Traditional coatings are semi-permeable, so do not fully water-proof or seal the coated electronics. They provide resistance to environmental exposure, which increases PCB durability while still keeping application and repair processes practical.

These categories are based on the basic resin of each coating. The chemistry determines the major attributes and functions of the conformal coating. Choosing the proper conformal coating for your application is determined by operational requirements of the electronics.

- Acrylic Resin (AR) – Acrylic conformal coating provides fair elasticity and general protection. Acrylic conformal coating is recognized for its high dielectric strength, and fair moisture and abrasion resistance. What generally distinguishes acrylic coating from other resins is ease of removal. Acrylic coatings are easily and quickly removed by a variety of solvents, often without the need of agitation. This makes rework and even field repair very practical and economical. On the other hand, acrylic coatings do not protect against solvents and solvent vapors, for example that might be typical for pumping equipment. Acrylic coatings can be considered basic entry-level protection, because they are economical and protect against a broad-level of contamination, but not best-in-class for any characteristic except possibly dielectric strength.

- Silicone Resin (SR) – Silicone conformal coating provides excellent protection in a very wide temperature range. SR provides good chemical resistance, moisture and salt spray resistance, and is very flexible. Silicone conformal coating isn’t abrasion resistant because of its rubbery nature, but that property does make it resilient against vibrational stresses. Silicone coatings are commonly used in high humidity environments, like outdoor signage. Special formulations are available that can coat LED lights without color shift or reduction of intensity. Removal can be challenging, requiring specialized solvents, long soak time, and agitation like from a brush or an ultrasonic bath.

- Urethane (Polyurethane) Resin (UR) – Urethane conformal coating is known for its excellent moisture and chemical resistance. They are also very abrasion resistant. Due to this and their solvent resistance, they are also very difficult to remove. Like silicone, full removal generally requires specialized solvents, long soak time, and agitation like from a brush or an ultrasonic bath. Urethane conformal coating is commonly specified for aerospace applications where exposure to fuel vapors is a common concern.

The scope of the rest of this post is concerned mainly with what we call “traditional” conformal coatings, but we’ll cover other coating types here to provide a complete picture of the available options.

- Epoxy Conformal Coating

Epoxy resins (ER) are usually available as two‐part compounds and create a very hard coating. The epoxy conformal coating provides very good humidity resistance and isn’t generally permeable like conformal coatings are. They also have high abrasion and chemical resistance. Typically, they are very difficult to remove once they are cured, and are not as flexible as the other materials. Epoxy coatings are common in potting compounds, which in contrast to conformal coatings, completely covers the electronics in a solid and level layer of material. - Parylene Conformal Coating

Parylene conformal coatings is a unique type of coating applied by vapor phase deposition. It provides excellent dielectric strength and superior resistance to moisture, solvents and extreme temperatures. Because of the vapor deposition method, parylene coatings can be applied very thin and still provide excellent circuit board protection. Removal for rework is very difficult, requiring abrasion techniques, and without access to vapor phase deposition equipment, recoating with parylene is impossible. - Thin Film / “Nano” Coatings

A coating is dissolved in a fluorocarbon‐based carrier solvent and applied with a spray or dip method to create a very thin coat, although not nanometer scale as the nickname suggests. They are commonly used to provide a minimal amount of hydrophobicity, which may prevent shortages from very quick exposure to water. This type of coating does not offer the level of the surface protection of other coating methods.

Don’t let extreme temperatures damage your products and parts! Keep them cool this summer with our conformal coating services.

CONFORMAL COATING TYPES

CONFORMAL COATING TYPES