Our Automated X-Ray Inspection Catches What the Eye Can’t See

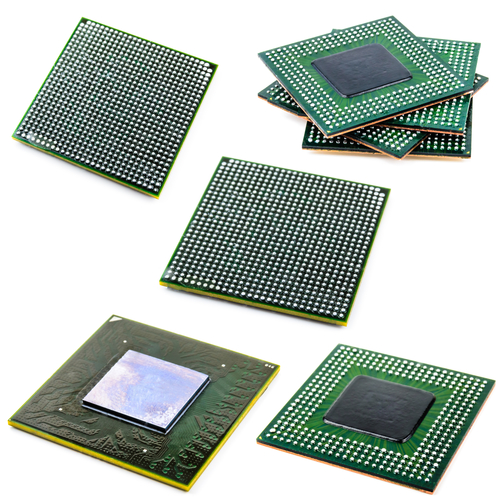

When manufacturing a printed circuit board, many components are hidden from the human eye. Even those parts that are visible are very small, making it difficult to effectively inspect a circuit board for defects.

At Yun Industrial Acme PCB Assembly, we have integrated several different inspection processes into our overall workflow system. These include quality inspection clips and automated optical inspection. Another part of our inspection process is the Automated X-ray Inspection. To perform this inspection, we use X-ray technology to look beneath the surface of the printed circuit board. This allows us to see every aspect of the PCB to look for defects and anomalies.

X-ray inspection systems for BGAs and CSPs are mainly classified into two categories: 2D (two dimensional) system and 3D (three dimensional) system. All the devices can be operated off line and are capable of making panel inspection and sampling inspection. Off line devices make it convenient to inspect PCBs at any stage in the assembly line and easy to be back to the assembly line again. Some X-ray devices are used on-line so that most of these devices are put after reflow oven. Whether to use on-line or off-line devices relies on the application and inspection amount. Generally speaking, online devices are suitable for applications with large quantity, complexity and few type changes based on the extra cost and safety elements.

A 2D X-ray system is capable of displaying simultaneously the 2D images of all the components from both sides of PCB just like the medical application used to inspect the bone fracture conditions. A 3D X-ray system is capable of generating the images of cross sections by rebuilding a series of 2D images just like the medical application, CT. Besides its cross section inspection, 3D system has another method which is Laminography. The inspection process is carried out by combining the image of a cross section and eliminating the images from other cross sections to rebuild the image of a certain cross section. 2D systems can be operated on line or off line.

The result is that we can catch more errors and offer our clients tested and proven PCBs that will work like a charm in their products.