Understanding Through-Hole Technology

At Yun Industrial Acme PCB Assembly, we offer a service called through-hole assembly, also known as “tru-hole assembly.” What is this service, and is it something you should consider for your next printed circuit board project?

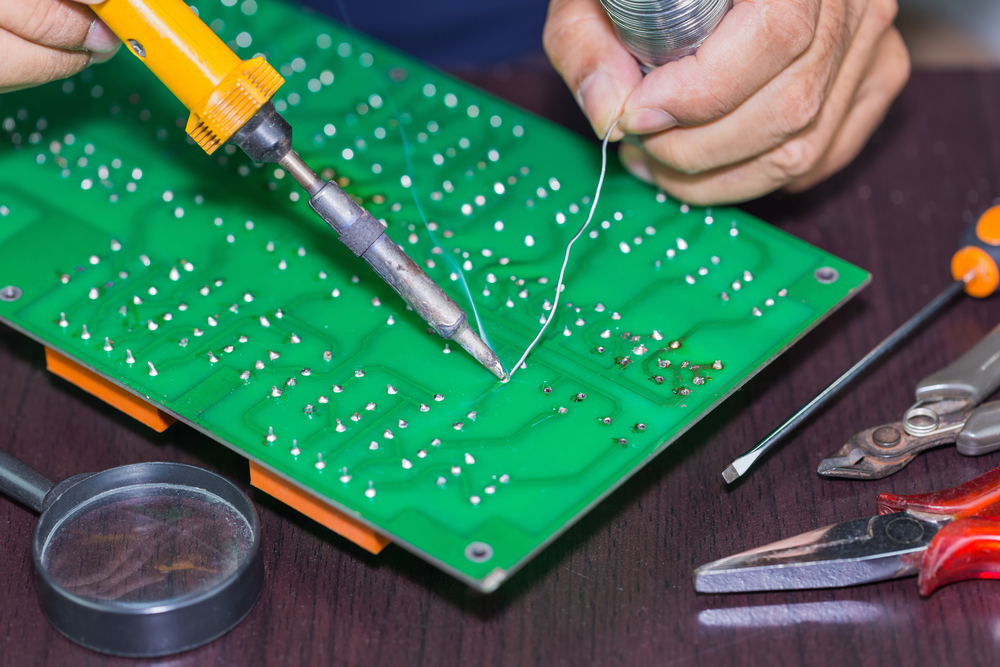

The defining characteristic of through-hole assembly is that holes are drilled through the printed circuit boards, and the PCB leads are inserted through those holes and soldered onto the opposite sides. Through-hole assembly has been around since the 1950s. Though much through-hole assembly has been replaced by surface-mount technology, there are still some uses for through-hole. For example, they can be used to make interconnections between layers on SMT boards.

The defining characteristic of through-hole assembly is that holes are drilled through the printed circuit boards, and the PCB leads are inserted through those holes and soldered onto the opposite sides. Through-hole assembly has been around since the 1950s. Though much through-hole assembly has been replaced by surface-mount technology, there are still some uses for through-hole. For example, they can be used to make interconnections between layers on SMT boards.

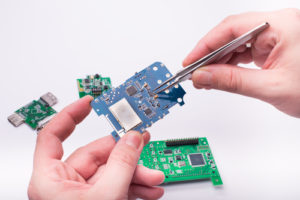

Technology is moving more and more towards a connected society and size does matter when it comes to PCB design. In the drive for ubiquitous computing, IoT or the “ambient intelligence” we are want so the drive to make smaller and smaller components includes the very heart of the electronic devices, the board.

Smaller components enable smaller boards, allowing us to fit printed boards in smaller devices. Smaller sizes mean less to manufacture leading to cost reductions in the production process. Less expensive components will lead to cost savings to the final customer.

Not sure if through-hole printed circuit boards are the way to go with your project? Give us a call and tell us what you want to make. Our knowledgeable representatives can help you determine what type of printed circuit boards would be best suited from your project.