When it comes to building reliable and high-performance Printed Circuit Boards (PCBs), two primary component-mounting methods dominate the industry: Through-Hole Technology (THT) and Surface Mount Technology (SMT). Each method has its advantages, disadvantages, and ideal use cases depending on the application.

At Yun Industrial Acme PCB Assembly, we specialize in both techniques—because the right choice depends on your project’s specific requirements. Let’s break down the differences between SMT and THT and explore which option might be better for your next design.

What Is Through-Hole Technology?

What Is Through-Hole Technology?

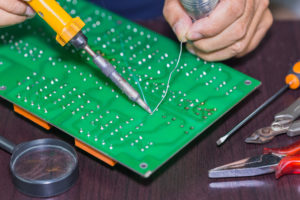

Through-Hole Technology involves inserting component leads through pre-drilled holes in the PCB and soldering them on the opposite side. This method was the industry standard for decades and is still used in applications where durability and mechanical strength are essential—like aerospace, automotive, and industrial equipment.

✅ Advantages:

- Strong mechanical bond—great for components that may face physical stress

- Ideal for high-power or high-voltage applications

- Easier to prototype and manually assemble

❌ Disadvantages:

- Takes up more board space

- Requires drilling, which increases fabrication cost and time

- Not ideal for high-density or compact designs

What Is Surface Mount Technology?

Surface Mount Technology involves placing components directly onto the surface of the PCB without the need for drilling holes. SMT has become the go-to method in modern electronics manufacturing due to its compact size and automated assembly compatibility.

✅ Advantages:

- Components are smaller and lighter

- Enables high-density designs for compact electronics

- Faster, more cost-effective automated assembly

- Allows components on both sides of the PCB

❌ Disadvantages:

- May not withstand as much mechanical stress as through-hole components

- Not suitable for all types of components, such as large connectors or transformers

- More challenging to prototype or hand-solder

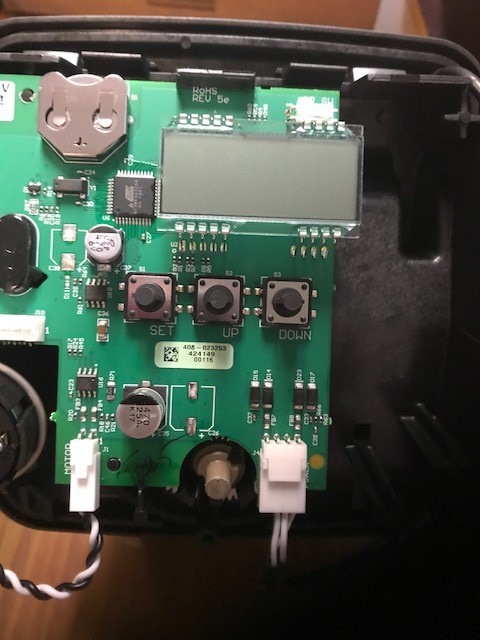

Can You Use Both SMT and Through-Hole on the Same PCB?

Can You Use Both SMT and Through-Hole on the Same PCB?

Absolutely. Many complex PCB designs today use a hybrid approach, combining both SMT and through-hole components. For example, delicate signal-processing components may be mounted with SMT, while connectors or high-power components use through-hole mounting for extra stability.

At Yun Industrial, we often recommend a mix of both technologies depending on your performance, space, and durability needs.

Which Technology Is Better?

There’s no one-size-fits-all answer. If your priority is size, speed, and automation, Surface Mount Technology is often the better choice. However, if your application requires strong mechanical bonds or involves large, heavy components, Through-Hole Technology may still be the right solution.

Partner with a PCB Assembly Expert

Choosing between SMT and THT isn’t just about the components—it’s about the performance of your entire product. At Yun Industrial Acme PCB Assembly, we’ll help you select the best technology for your PCB, whether it’s surface mount, through-hole, or both.

👉 Learn more about our capabilities and how we can support your next PCB project: https://yic-assm.com

What Is Through-Hole Technology?

What Is Through-Hole Technology? Can You Use Both SMT and Through-Hole on the Same PCB?

Can You Use Both SMT and Through-Hole on the Same PCB?