Consider a Conformal Coating for Your Printed Circuit Boards

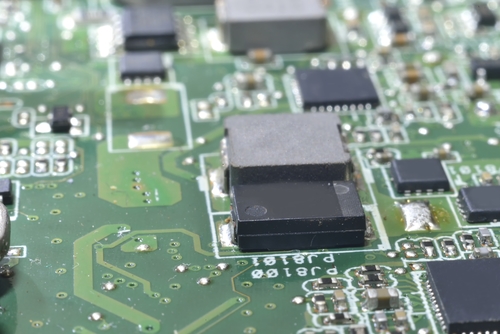

We all know that electronic equipment doesn’t hold up well against the elements without a little help. The same is true of printed circuit boards. The delicate traces, wiring, components, and insulation can easily be damaged by exposure to chemicals, contaminants, and especially moisture. No company wants its electronic products to quickly fail as soon as they are out of the box, so how can manufacturers protect their products and specifically the printed circuit boards within?

What Is Conformal Coating?

Conformal coating is a light chemical coating that is sprayed, brushed, or dipped onto a printed circuit board. The coating acts like a shield to protect the components of the PCB from elemental dangers. Different conformal coatings are designed to protect against specific environmental threats. The most common types of coatings are:

- Acrylic conformal coating

- Urethane conformal coating

- Silicone conformal coating

Benefits of Conformal Coating

The primary benefit of a conformal coating is its protective quality. Its ability to limit the damage of different environmental contaminants means that your printed circuit boards can function better and last longer even under stressful conditions. It also means that equipment can be used for many different purposes that might not be possible without conformal coating.

The primary benefit of a conformal coating is its protective quality. Its ability to limit the damage of different environmental contaminants means that your printed circuit boards can function better and last longer even under stressful conditions. It also means that equipment can be used for many different purposes that might not be possible without conformal coating.

For example, a product that operates on a ship can be highly vulnerable to corrosive sea water. A conformal coating can help keep the moisture and salt out or even allow moisture in the circuit board to escape.

Other benefits of conformal coating include:

- Conductor spacing can be radically reduced

- Lightweight coating allows for smaller, lighter PCBs

- Reduces or eliminates the need for complex enclosures to protect PCBs

- Also protects against thermal and mechanical stress

- Easy application

How to Apply a Conformal Coating

Conformal coating is applied over the entire PCB assembly, including the sharp edges and contours. Once the coating is applied, it needs to be cured (dried), which can be done by:

- UV light curing

- Air drying

- Over drying

Printed circuit board manufacturers, like Yun Industrial Acme PCB Assembly, are skilled at providing conformal coating to PCB prototypes and PCB orders.

Want to learn more about our conformal coating services or need help determining which conformal coating is ideal for your product? Contact us today.