Maintaining and troubleshooting your PCBs (Printed Circuit Boards) is essential to ensuring the long-term performance of your electronic devices. Whether you’re dealing with high-end industrial equipment or everyday electronics, understanding the intricacies of PCB care can prevent costly downtime and improve the efficiency of your operations. At the core of every reliable system is quality assembly, and with Yun Industrial PCB Assembly, you can have confidence in both the longevity and functionality of your boards. But once you’ve got the right assembly in place, how do you keep it running smoothly?

Maintaining and troubleshooting your PCBs (Printed Circuit Boards) is essential to ensuring the long-term performance of your electronic devices. Whether you’re dealing with high-end industrial equipment or everyday electronics, understanding the intricacies of PCB care can prevent costly downtime and improve the efficiency of your operations. At the core of every reliable system is quality assembly, and with Yun Industrial PCB Assembly, you can have confidence in both the longevity and functionality of your boards. But once you’ve got the right assembly in place, how do you keep it running smoothly?

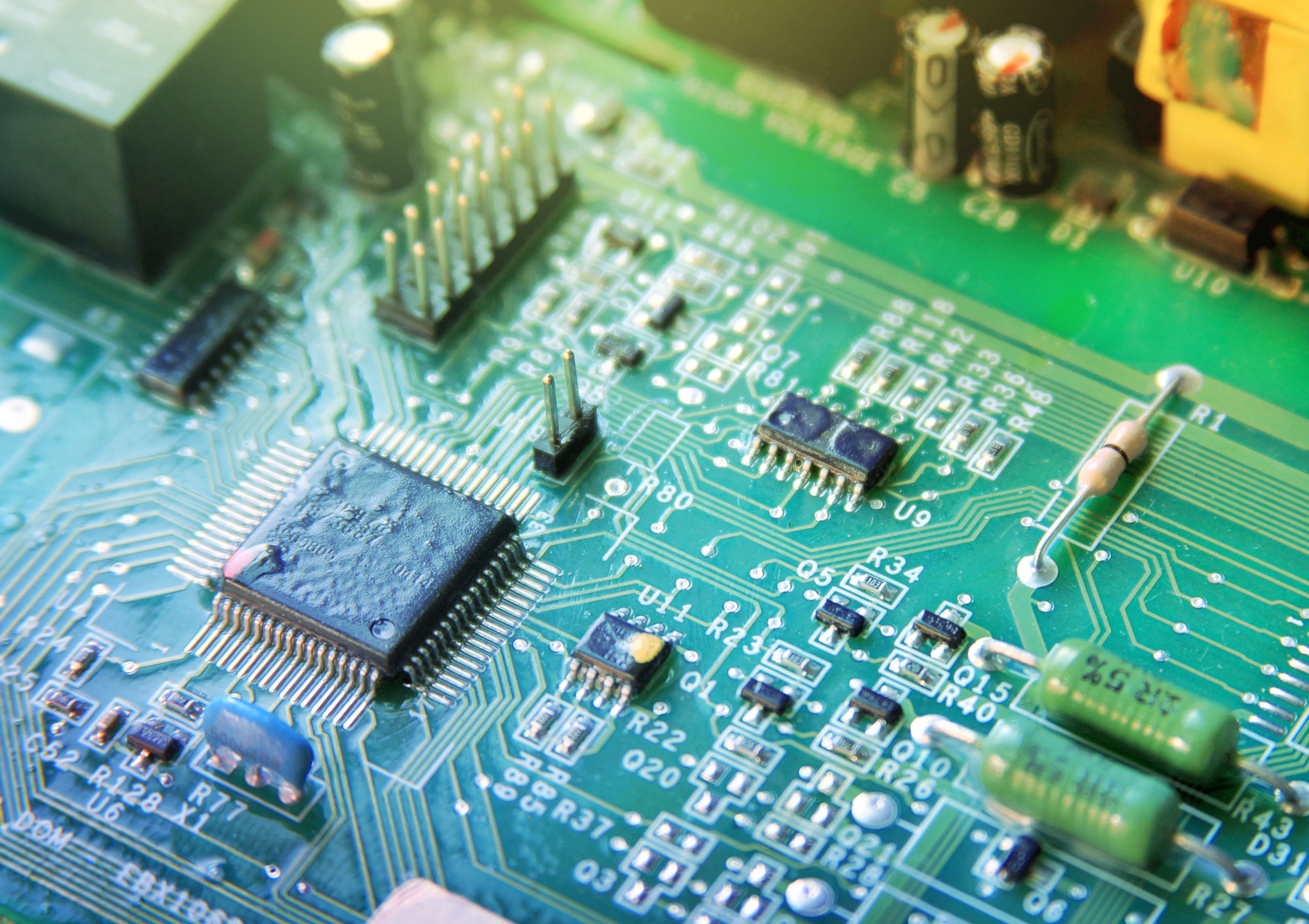

The first step in maintaining your PCBs is understanding how environmental factors can impact their performance. Dust, humidity, and temperature extremes can affect the components and solder joints on your board. For instance, if a PCB is exposed to high humidity, it may lead to oxidation, which can weaken connections and eventually cause failures. Regularly checking and cleaning your PCBs helps mitigate these risks, ensuring that external factors do not interfere with the delicate circuits. When using Yun Industrial PCB Assembly, the robust design and high standards in manufacturing already provide an advantage in combating such environmental challenges, but routine maintenance is still crucial.

Another key aspect of maintaining PCBs is recognizing the early signs of wear or damage. Even the best-assembled boards can face issues over time, especially in complex systems. One of the most common problems is the gradual loosening or breaking of solder joints, often caused by repeated heating and cooling cycles. This can lead to intermittent issues, where devices may work fine one moment and fail the next. Spotting these problems early can save significant troubleshooting time. Yun Industrial PCB Assembly ensures that solder joints are crafted with precision, but monitoring for any anomalies, such as unusual heat or resistance, is important to avoid larger issues.

When it comes to troubleshooting, identifying the root cause of PCB issues can often feel like looking for a needle in a haystack. A solid approach is to isolate sections of the board and test them individually. This might involve using diagnostic tools like multimeters to check for continuity or voltage levels. Additionally, thermal cameras can be used to detect any hotspots that indicate malfunctioning components. With Yun Industrial PCB Assembly, troubleshooting can be more straightforward, as the quality control processes during manufacturing are designed to minimize errors, meaning any faults are more likely to arise from external influences or age, rather than poor construction.

Sometimes, a malfunctioning PCB may be the result of software-related issues, particularly in boards connected to more advanced systems. In such cases, resetting the firmware or software settings might resolve problems that hardware troubleshooting cannot address. However, for purely hardware-based issues, it is important to focus on the connectors, capacitors, and resistors, as these are the most common points of failure. By paying close attention to these elements, you can often resolve issues without needing to replace the entire board.

In conclusion, maintaining and troubleshooting your PCBs comes down to proactive care, early detection of issues, and methodical diagnostics. With Yun Industrial PCB Assembly, you are already starting from a position of strength, as the assembly quality reduces the likelihood of many common issues. By combining this with routine checks and a thoughtful approach to troubleshooting, you can extend the life of your PCBs and ensure the reliability of your electronic systems.