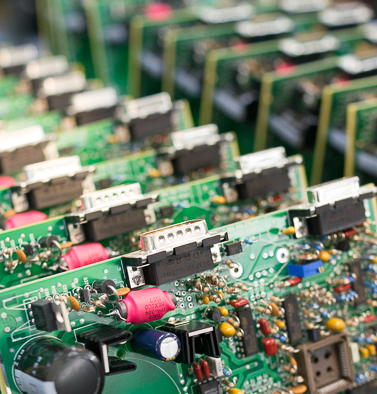

Simplify Manufacturing with Turnkey PCB Assembly

In the fast-paced world of electronics manufacturing, efficiency is everything. Companies need streamlined processes that reduce lead times, cut costs, and ensure high-quality production. Turnkey PCB Assembly is a solution that does just that—offering a seamless, hassle-free approach to printed circuit board (PCB) production.

But what exactly is turnkey PCB assembly, and why is it essential for your business? Let’s break it down.

What is Turnkey PCB Assembly?

Turnkey PCB assembly is a one-stop solution for PCB production. Instead of managing multiple suppliers for components, PCB fabrication, and assembly, a turnkey provider handles everything—from sourcing materials to final testing.

At YIC Assembly, our turnkey PCB assembly services simplify the entire process, ensuring efficiency, cost savings, and high-quality results.

How Turnkey PCB Assembly Works

With a turnkey approach, your PCB assembly partner takes care of:

With a turnkey approach, your PCB assembly partner takes care of:

✔ Component Sourcing – Procuring high-quality components from reliable suppliers.

✔ PCB Fabrication – Manufacturing the PCB boards to exact design specifications.

✔ Assembly – Mounting components using SMT or through-hole technology.

✔ Testing & Quality Control – Ensuring each board functions correctly before shipment.

✔ Logistics & Delivery – Streamlining shipping and fulfillment to meet production deadlines.

Instead of coordinating multiple vendors, you hand off your PCB design files to one provider and receive a fully assembled, tested product—ready for use.

Why Does Your Business Need Turnkey PCB Assembly?

1. Faster Production and Reduced Lead Times

Time is money in manufacturing. Turnkey PCB assembly eliminates delays caused by miscommunication between suppliers. With all processes handled under one roof, production cycles are significantly shorter.

2. Cost Savings

Outsourcing to multiple vendors increases overhead. Turnkey solutions reduce costs by optimizing procurement, minimizing waste, and lowering labor expenses.

3. Higher Quality Control

Managing different suppliers often leads to inconsistencies in production. With turnkey PCB assembly, quality control is centralized, ensuring consistency and reducing the risk of defects.

4. Streamlined Supply Chain Management

Juggling multiple suppliers, lead times, and logistics is complex. Turnkey PCB assembly simplifies supply chain management, allowing your business to focus on product innovation and market expansion.

5. Scalability for Growing Businesses

Whether you need a small batch for prototyping or a large-scale production run, turnkey assembly adapts to your business needs. This flexibility makes it ideal for startups and established manufacturers alike.

Ready to Simplify Your PCB Manufacturing?

Ready to Simplify Your PCB Manufacturing?

Turnkey PCB assembly is the fastest, most cost-effective way to bring your electronics projects to life. By consolidating procurement, fabrication, and assembly under one provider, your business gains efficiency, quality assurance, and a competitive edge.

At YIC Assembly, we specialize in turnkey PCB assembly solutions tailored to your exact specifications. Whether you’re developing consumer electronics, industrial controls, or medical devices, we provide the precision, speed, and reliability your business needs.

Let’s get started!

Contact us today for a quote and experience the benefits of turnkey PCB assembly firsthand.

Ready to Simplify Your PCB Manufacturing?

Ready to Simplify Your PCB Manufacturing?