Understanding Flexible Circuits: Applications and Advantages

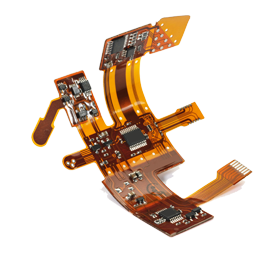

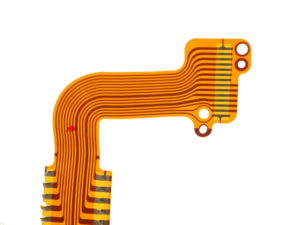

Flexible circuits, also known as flex circuits or flex PCBs, are widely used as connectors in applications where flexibility, space savings, or construction constraints limit the use of traditional rigid circuit boards or hand wiring. These circuits are designed to bend, twist, and fold, making them ideal for compact, lightweight, and dynamic electronic systems.

Flexible Displays and Advanced Substrates

In LCD fabrication, rigid glass is traditionally used as a substrate. However, when thin, flexible plastic or metal foil is used instead, the entire display can become bendable. The thin film deposited on top—typically just a few micrometers thick—enables this flexibility.

Organic light-emitting diodes (OLEDs) are commonly used in flexible displays, replacing traditional backlights. This makes flexible OLED displays a preferred choice in cutting-edge consumer electronics like foldable phones and rollable screens.

Common Applications of Flexible Circuits

Common Applications of Flexible Circuits

While some flex circuits serve as passive wiring structures for interconnecting components like resistors, capacitors, and ICs, many are designed to connect different electronic assemblies directly or via connectors.

Here are some of the most common industries and applications where flexible circuits are used:

Automotive Industry

Instrument panels and dashboards

Under-hood control systems

Circuits integrated into headliners

ABS system wiring

Computer Peripherals

Moving print heads in printers

Read/write head arms in disk drives

Consumer Electronics

Cameras and camcorders

Wearable fitness devices and smartwatches

Calculators and handheld gadgets

Medical and Industrial Equipment

Compact interconnects in diagnostic devices

Flexible wiring for robotic systems

Control circuits in manufacturing equipment

Mobile Devices

Cell phones and smartphones

Tablets and compact computing devices

Compact, Reliable, and Versatile

Flexible circuits offer space-saving advantages, durability, and mechanical versatility, which is why they’re so prevalent in modern electronics. As demand for lighter, more dynamic, and wearable technologies grows, so too does the importance of flexible PCB design and manufacturing.

Let’s Talk About Your Flexible Circuit Needs

Let’s Talk About Your Flexible Circuit Needs

Have questions about flexible circuits or need help with your PCB design? Whether you’re building a medical device, automotive solution, or next-gen consumer tech, we’re here to help.

Contact us today to learn more or request a quote.

Common Applications of Flexible Circuits

Common Applications of Flexible Circuits Let’s Talk About Your

Let’s Talk About Your