The Benefits of PCB Manufacturing and Turn-key Assembly in California and the USA

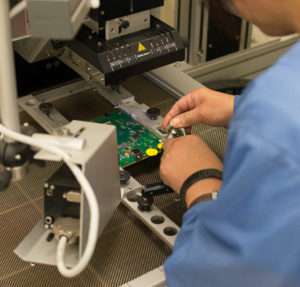

In today’s fast-paced electronics industry, companies are constantly looking for ways to optimize production, cut costs, and improve product quality. This is where Turnkey PCB Manufacturing and Assembly in the USA comes in as a game-changing solution.

Unlike traditional PCB assembly, which requires managing multiple vendors for fabrication, components, and assembly, turnkey PCB assembly streamlines the entire process. Companies like YIC – Your Industrial Connection offer comprehensive turnkey PCB solutions, combining fabrication, sourcing, and assembly under one roof — saving time, money, and effort.

Here are the top benefits of PCB Manufacturing and Turn-key Assembly in California and the USA:

1) Reduced Costs and Streamlined Production

One of the most significant benefits of turnkey PCB manufacturing and assembly is cost reduction.

- Consolidated services mean you don’t have to pay separate fees for fabrication, sourcing, and assembly.

- Reduced freight costs: Imagine coordinating shipments from PCB manufacturers, component suppliers, and assembly houses — the freight and logistics costs can add up fast. Turnkey solutions eliminate these expenses.

- Better pricing on components: Turnkey PCB providers often have established relationships with trusted component suppliers, enabling them to negotiate better prices, which are passed on to customers.

By partnering with an experienced provider like YIC, companies can drastically reduce the total cost of production while enjoying high-quality assembly services.

2) High-Quality Components and Sourcing Expertise

Sourcing the right components can be challenging, especially when facing market shortages or counterfeit risks.

With turnkey PCB assembly, component procurement is handled by experts who work closely with verified manufacturers and distributors. This ensures:

- Top-quality components that meet required specifications.

- Avoidance of counterfeit or low-grade parts.

- Access to customized components and consigned inventory management.

At YIC, we not only handle procurement but also manage customer-supplied materials and offer inventory reports, giving you complete visibility over your components.

3) Faster Turnaround and Shorter Lead Times

3) Faster Turnaround and Shorter Lead Times

One of the key benefits of PCB manufacturing and turn-key assembly in California is reduced lead time.

When managing multiple vendors, you must deal with:

- Separate quotes.

- Multiple points of contact.

- Coordination of timelines between different stages (fabrication, component sourcing, assembly).

Turnkey assembly eliminates all of these steps. By working with a single provider, the entire process is streamlined, reducing turnaround time and ensuring on-time delivery. Whether it’s small prototype runs or full production, companies like YIC ensure speed and efficiency.

4) Simplified Monitoring and Single Point of Contact

Managing different vendors requires tracking progress at each stage, increasing your workload and risks of miscommunication.

With turnkey PCB assembly, you get:

- One point of contact for all updates and questions.

- Real-time process tracking through customer portals.

- Professional in-house engineering teams overseeing each step, from PCB fabrication to final testing.

This makes project management easier and less stressful, and you maintain full control over timelines and quality.

5) Easier and More Efficient Prototyping

Prototyping is a critical phase in any electronics project. Traditional methods require separate vendors for each stage, leading to:

- Increased costs.

- Longer timelines.

- Possible errors and mismatches.

Turnkey PCB manufacturing and assembly streamlines prototyping by offering:

- One-stop service based on your product specs.

- Expert design review and engineering feedback to refine prototypes.

- Faster transition from prototype to production.

At YIC, seasoned professionals handle prototyping, ensuring higher quality and more accurate prototypes that help accelerate product development cycles.

6) Early Problem Detection and Reduced Risk

A costly mistake many companies encounter in traditional PCB assembly is discovering errors after components are ordered or boards are fabricated — leading to expensive rework.

With turnkey PCB assembly, early detection of issues happens because:

- The same team reviews your design, sources components, and performs assembly, ensuring alignment.

- Integrated quality checks are performed at every stage.

- Potential mismatches between board specs and components are identified before production, saving time and money.

YIC’s in-house engineering and quality control teams work proactively to avoid costly errors — taking full responsibility for the final product.

7) Inventory Management and Material Control

In addition to standard turnkey services, YIC also offers:

- Consigned and customized component management.

- Shortage and bin inventory reports for better supply chain visibility.

- Just-in-time inventory for Level A custom components, ensuring parts are available when you need them without overstocking.

This inventory support is an added value, helping customers manage component availability and costs more effectively.

Why Choose Turnkey PCB Manufacturing and Assembly in California and the USA?

Why Choose Turnkey PCB Manufacturing and Assembly in California and the USA?

Choosing Turnkey PCB Manufacturing and Assembly in the USA with a trusted partner like YIC ensures:

- Faster lead times with domestic production.

- Better quality control and compliance with U.S. manufacturing standards.

- Reduced costs through consolidated services and optimized sourcing.

- Lower risk and higher quality from start to finish.

- Simplified process management with a single vendor and point of contact.

Whether you need rapid prototyping, small-batch production, or high-volume assembly, YIC’s turnkey PCB services are designed to help you succeed — on time and on budget.

Ready to Streamline Your PCB Projects?

Contact YIC today to learn more about how Turnkey PCB Manufacturing and Assembly in the USA can improve quality, reduce costs, and simplify production.

3) Faster Turnaround and Shorter Lead Times

3) Faster Turnaround and Shorter Lead Times Why Choose Turnkey PCB Manufacturing and Assembly in California and the USA?

Why Choose Turnkey PCB Manufacturing and Assembly in California and the USA?