There are a few fundamental constructions of flexible circuit boards, but there is an important variation between the different types of conditions in their production. Following is an evaluation of the most general types of flexible circuit board constructions.

Single-sided Flexible Circuits

Single-sided Flexible Circuits

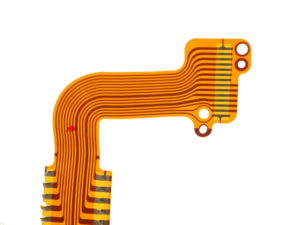

Single-sided flexible circuits contain a single conductor layer prepared of either a metal or conductive (metal filled) polymer on a flexible dielectric film. Component execution features are available only from one side. Holes may be created (drilled or laser) in the base film to allow component leads to pass during for interconnection, usually by soldering. Single sided flex circuits are able to be fabricated with or without such protective coatings as cover layers or cover coat, nevertheless the use of a protective coating above circuits is the most common practice.

The implement of surface mounted devices on sputtered conductive films have enabled the manufacture of apparent LED Films, which is used in LED Glass but moreover in flexible automotive lighting composites.

Double- Sided Flexible Circuits

Double-sided flex circuit boards are a flex circuits have two conductor layers. Thesis flex circuits can be fabricated with or without plated through holes, though the plated through hole variation is much more general. When construct without plated through the holes and association features are access from one side simply, the circuit is a defined as a “Type-5” according to the military condition.

It is not a general practice, but it is an option, terminations for electronic apparatus are provided for on both sides of the circuit, thus allow the apparatus to be placed on each side. Depending up on design necessities, double-sided flex circuits can be fabricated with protecting cover layers in one, both or neither side of the finished circuit, but are mainly frequently formed with the protective layer on both sides. One major benefit of this type of substrate is that it allows intersect connections to be prepared very easily. Many single sided circuits are built on a double sided substrate immediately since they have one of two intersect connections.

Sculptured Flexible Circuits

Sculptured flex circuits are a novel separation of typical flexible circuit structures. The developed procedure involves a particular flex circuit multi-step etching method which yields a flexible circuit have finished copper conductors wherein the thickness of the conductor differs in several places along their length. (i.e. the conductors are thin in flexible areas and thick at interconnection points).

Multi-layer Flexible Circuits

Multi-layer Flexible Circuits

Flex circuits have three or additional layers of conductors are known as multi-layer flex circuits. Normally the layers are interconnected by means of plated through holes, though this is not a condition of the definition for it is probable to supply openings to access lower circuit level features. The layers of the multi-layer flex circuit may or may not be incessantly laminated mutually throughout the building with the noticeable exemption of the areas engaged by plating through-holes. The practice of irregular lamination is familiar with cases where utmost flexibility is compulsory. This is accomplished by leaving unbounded the areas wherever flexing or bending is to happen.

Rigid-Flex Circuits

Rigid-flex circuits are a hybrid manufacture flex circuit consisting of rigid and flexible substrates which are laminated mutually into a single structure. Rigid-flex circuits must not be confused with rigidized flex constructions are just flex circuits to which a stiffener is attached to maintain the weight of the electronic apparatus locally. A rigidized or stiffened flex circuit can contain one or extra conductor layers. Thus, while the two terms might sound comparable, they signify products that are reasonably dissimilar. The layers of a rigid flex are also usually electrically interconnected by means of plated through holes. Over the years, rigid-flex circuits include wonderful popularity among military product designer; though the technology has found improved use in commercial products.

Yun Industrial / ACMS PCB will work with you for all of your flexible circuit board, flexible circuit board assembly needs. We are committed to not only customer satisfaction, but exceeding our customer’s expectations. Our adherence to quality standards is a part of what makes our boards superior to other suppliers.

Single-sided Flexible Circuits

Single-sided Flexible Circuits Multi-layer Flexible Circuits

Multi-layer Flexible Circuits