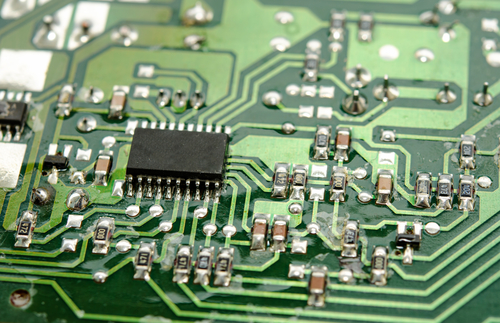

When it comes to selecting the right printed circuit board (PCB) for your application, the decision isn’t as straightforward as it might initially seem. PCBs are the backbone of modern electronics, providing the necessary structure and connections for the components that make up your device. Whether you’re working on a simple consumer product or a complex industrial machine, the right PCB design and material choice can significantly impact the performance, reliability, and cost of your product.

The first step in choosing the right PCB is to understand the specific requirements of your application. This involves considering the environment in which the PCB will operate, the electrical performance needed, and the mechanical demands it will face. For instance, if your application involves high-frequency signals, you’ll need a PCB that can handle these without significant signal loss. In contrast, if your product will be exposed to harsh environmental conditions, such as extreme temperatures or humidity, you’ll need a PCB that’s durable and resistant to such factors.

The first step in choosing the right PCB is to understand the specific requirements of your application. This involves considering the environment in which the PCB will operate, the electrical performance needed, and the mechanical demands it will face. For instance, if your application involves high-frequency signals, you’ll need a PCB that can handle these without significant signal loss. In contrast, if your product will be exposed to harsh environmental conditions, such as extreme temperatures or humidity, you’ll need a PCB that’s durable and resistant to such factors.

One of the key aspects to consider is the material used in the PCB. The most common material is FR-4, a composite made of woven fiberglass cloth with an epoxy resin binder. FR-4 is popular because it’s cost-effective and offers good electrical insulation properties. However, for high-frequency applications, materials such as Rogers or Teflon might be more suitable due to their lower dielectric losses. Understanding the trade-offs between cost, performance, and durability is crucial in making the right choice.

In addition to the material, the layout and design of the PCB are critical. A well-designed PCB can minimize issues like electromagnetic interference (EMI) and crosstalk, which can affect the performance of your device. At YIC-Assm, we specialize in creating custom PCB layouts that meet the specific needs of your application, ensuring optimal performance and reliability.

Another important consideration is the number of layers in your PCB. Single-layer PCBs are typically used in simpler devices, while multi-layer PCBs are required for more complex electronics. Multi-layer PCBs allow for more connections and can reduce the size of the device, but they also increase the manufacturing cost. It’s important to weigh these factors based on the complexity of your application and your budget.

Finally, it’s essential to work with a manufacturer that has the expertise and technology to deliver high-quality PCBs tailored to your needs. At YIC-Assm, we offer a range of PCB manufacturing services, from prototype development to large-scale production. Our team is dedicated to helping you choose the right PCB for your application, ensuring that your product meets the highest standards of performance and reliability.

Selecting the right PCB involves careful consideration of the material, design, and the specific needs of your application. By working with a trusted partner like YIC-Assm, you can be confident that you’re making the best choice for your product, ensuring its success in the market. Whether you’re developing a new device or improving an existing one, the right PCB is crucial to achieving the desired performance and longevity.