Bringing a new electronic product to market begins with a successful prototype. Prototype PCB assembly bridges the gap between design and production, allowing engineers to validate functionality, test performance, and refine designs before committing to full-scale manufacturing. A reliable prototype assembly partner is essential for transforming concepts into working hardware efficiently while minimizing development risk.

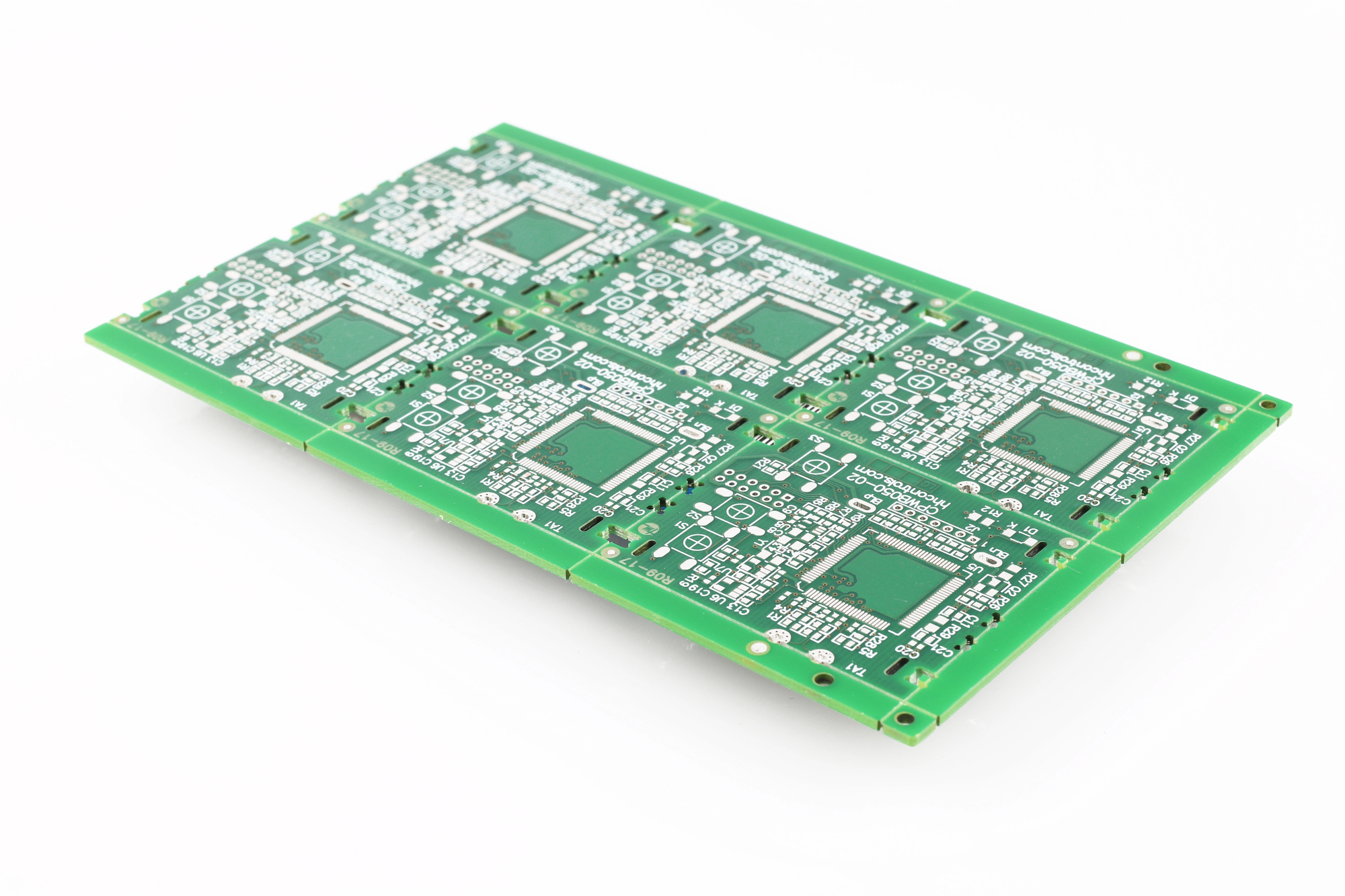

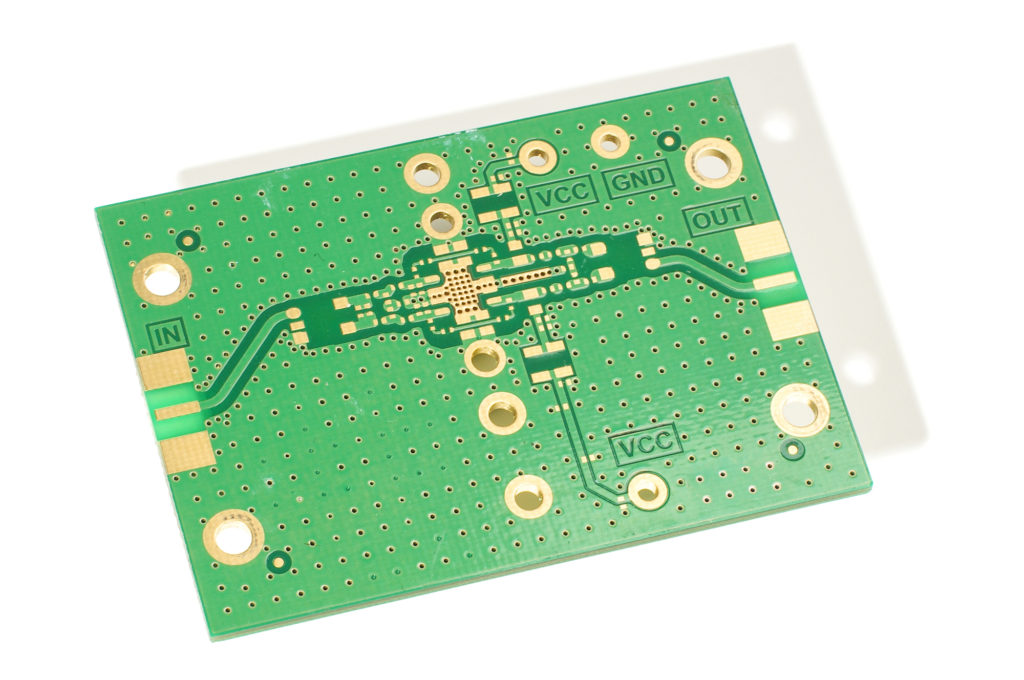

Prototype PCB assembly focuses on low-volume builds with a high level of attention to detail. Each board is assembled according to exact design specifications, ensuring an accurate representation of the final product. This critical phase allows development teams to identify design flaws, component compatibility issues, and performance limitations early in the process, when changes are less costly and easier to implement.

Speed and flexibility are especially important during prototyping. Design iterations are common, and turnaround time directly impacts development schedules and product launch timelines. Working with a manufacturer that offers integrated PCB fabrication and assembly helps reduce delays and streamline communication. Engineers benefit from faster revisions, fewer handoffs, and greater visibility into the manufacturing process, allowing them to make informed adjustments quickly.

YIC Assembly Services supports prototype PCB assembly with deep engineering insight and proven manufacturing expertise. From component sourcing and bill of materials review to assembly, inspection, and testing, each step is carefully managed to ensure prototypes meet functional and quality expectations. Design for manufacturability feedback is often incorporated during this stage, helping teams refine layouts and improve long-term production readiness.

Prototype assemblies are widely used across industries such as medical devices, Internet of Things applications, automotive electronics, telecommunications, and industrial automation. In each of these markets, early validation is critical. Accurate prototypes help uncover potential issues related to signal integrity, thermal performance, mechanical fit, and component selection before they scale into costly production problems.

Beyond functional testing, prototype PCB assembly supports regulatory review, customer demonstrations, and internal validation efforts. Regulatory agencies, investors, and stakeholders often require physical hardware to evaluate compliance, performance, and feasibility. A well-built prototype reflects the reliability and professionalism of the final product, building confidence among decision-makers and accelerating approvals.

High-quality prototype assembly also helps establish a smoother transition to production. When prototypes are built using production-ready processes and materials, manufacturers can scale more efficiently with fewer surprises. Lessons learned during prototyping directly inform process improvements and reduce rework during volume manufacturing.

By investing in high-quality prototype PCB assembly, companies shorten development cycles, reduce costly redesigns, and improve overall product outcomes. Choosing an experienced manufacturing partner ensures that prototypes are built right the first time, setting a strong foundation for successful production and long-term performance.