Yun Industrial specializes in Surface-Mount Technology (SMT) to apply components to the surface of PCBs. Keep in mind, you will need to do your homework before you move forward in switching an existing electronic product design from through-hole technology to surface mount technology (SMT).

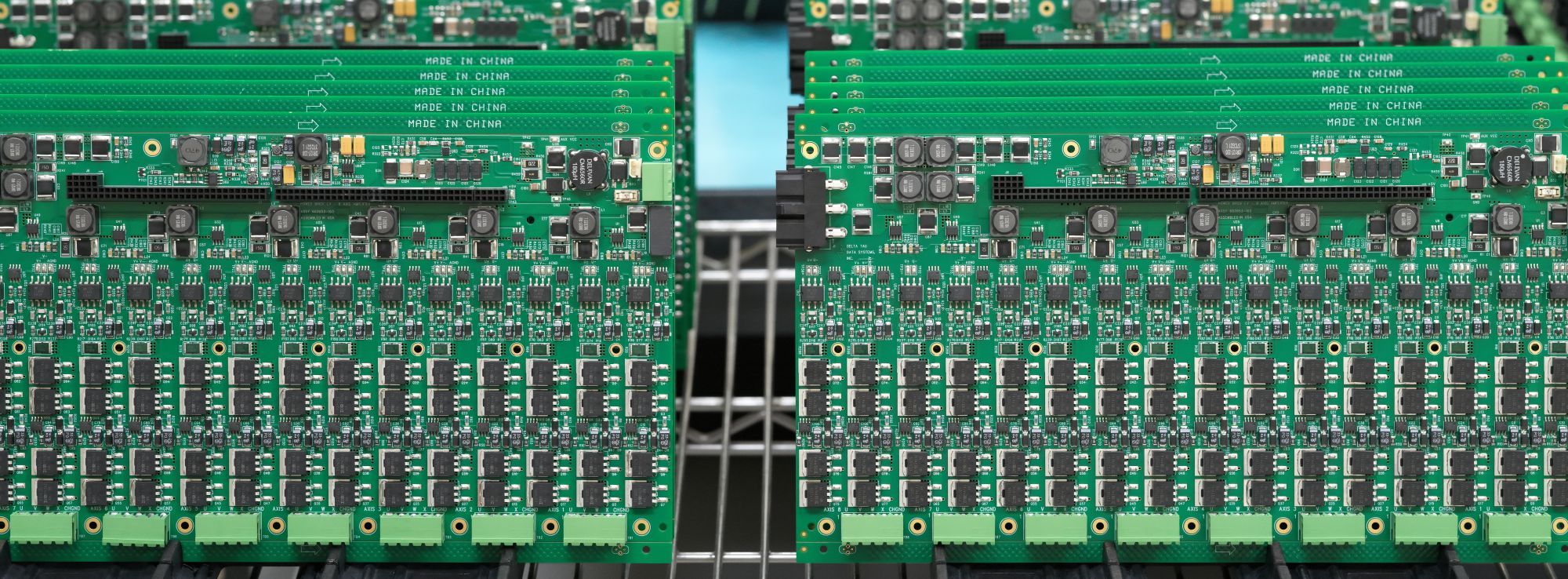

Surface-mount technology (SMT) is a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). The PCB industry has largely replaced the thru-hole technology construction method of fitting components with wire leads into holes in the circuit board. Both technologies can be used on the same board, with the thru-hole technology used for components not suitable for surface mounting such as large transformers and heat-sinked power semiconductors. To keep from making costly mistakes and facing critical challenges, you should make sure the SMT version of through-hole PCB designs are available, keep in mind of there is no shortage of the advantages you will see in surface mount technology.

An SMT component is usually smaller than its thru-hole counterpart because it has either smaller leads or no leads at all. It may have short pins or leads of various styles, flat contacts, a matrix of solder balls (BGAs), or terminations on the body of the component.

The checklist below are steps meant to help you in the transition, and will help you to make an informed decision.

1. MAKE SURE TRANSITION IS ACTUALLY A GOOD IDEA

Surface mount vs. through-hole, there are many advantages of SMT which include:

- Lower manufacturing costs. Once you get your SMT design up and running, you can expect to pay less for the cost of building your product. SMT is the go-to now for several reasons, and lower cost is one of those reasons.

- Uses less space. With a few possible exceptions, all the boards in your small mobile devices are SMT. Companies choose SMT because it takes up less space, which allows them to deliver more with less bulk.

- Faster manufacturing. What may take a few hours on a through-hole board can take five minutes on an SMT board.

2. REGULATORY CERTIFICATIONS

A few things tokeep in mind with a PCB development to help minimize issues with regulatory certifications:

- Allow as many deviations for component selection as you can. You may need to make changes to meet regulations.

- Determine the impact of the redesign on regulations. New approvals can seriously delay product roll out, so be aware of the strength of the upcoming approval cycle. The more changes you make, the more attention you will probably draw to your product.

- New components may have restrictions in certain parts of the world. Know the issues you might run into for every region in which you’ll sell your part.

3. REDESIGN CONSIDERATIONS

Reputable electronics design companies should be able to redesign most boards, but make sure it’s possible to convert your specific product. Questions you should ask include:

- Can you redesign the board?

- Can you find SMT versions of components that match the form and function of the through-hole components?

- Are there any features you’d like to add from a sales/marketing standpoint since you’re redesigning anyway?