Printed Circuit Board (PCB) technology has undergone significant transformations since its inception, becoming an integral component in modern electronics. Understanding the evolution of PCB technology provides insight into its current capabilities and future potential. In this article, we explore the history, advancements, and future trends in PCB technology, highlighting the role of innovation in shaping the electronic devices we rely on today.

The Early Beginnings

The concept of a PCB dates back to the early 20th century. In 1903, German inventor Albert Hanson described flat foil conductors laminated to an insulating board in multiple layers. This was the precursor to what we now know as printed circuit boards. However, it wasn’t until Paul Eisler, an Austrian engineer, developed the first true PCB in 1936 that the technology began to take shape. Eisler’s PCB was initially used in radios during World War II, marking the beginning of a new era in electronic circuitry.

The Rise of PCBs in Consumer Electronics

Post-World War II, PCBs started gaining traction in consumer electronics. The 1950s and 1960s saw a significant increase in the use of PCBs in televisions, radios, and other household appliances. This period also marked the standardization of PCB manufacturing processes, making them more reliable and cost-effective.

Advancements in PCB Manufacturing

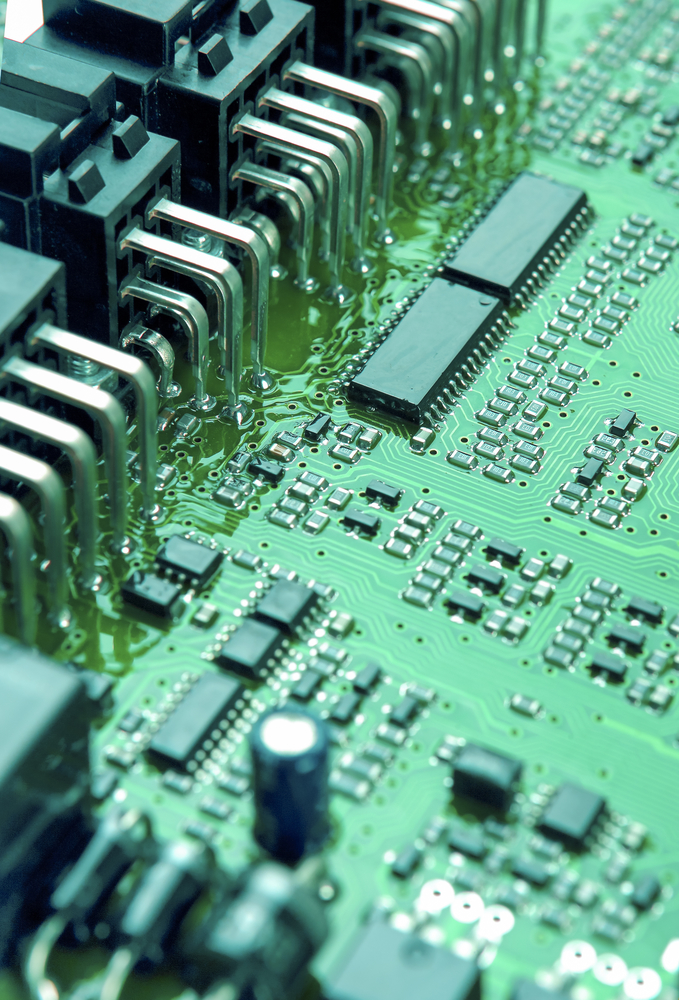

The 1970s and 1980s witnessed major advancements in PCB manufacturing. The introduction of automated processes and the development of surface mount technology (SMT) revolutionized the industry. SMT allowed for smaller and more complex circuits, enabling the miniaturization of electronic devices. The use of multiple layers in PCB design also became more prevalent, increasing the functionality and performance of electronic components.

The Impact of Computer-Aided Design (CAD)

The advent of computer-aided design (CAD) in the 1990s further transformed PCB technology. CAD tools allowed engineers to design complex circuits with high precision, reducing errors and improving efficiency. This era also saw the introduction of flexible PCBs, which offered greater versatility and application in various industries, including medical devices and wearable technology.

Modern PCB Technology

Today, PCBs are more advanced than ever before. High-density interconnect (HDI) technology has enabled the production of PCBs with finer lines and spaces, allowing for more compact and efficient designs. Innovations such as embedded components, which integrate passive and active components within the PCB layers, have further enhanced performance and reliability.

At YIC Assm, we leverage the latest advancements in PCB technology to deliver high-quality, reliable, and cost-effective solutions. Our state-of-the-art manufacturing processes ensure that our PCBs meet the stringent demands of various industries, from consumer electronics to aerospace and defense.

The Future of PCB Technology

Looking ahead, the future of PCB technology is promising. The rise of the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics will drive further innovation in PCB design and manufacturing. Flexible and wearable electronics are expected to become more prevalent, necessitating the development of new materials and fabrication techniques. Additionally, the ongoing push for environmental sustainability will lead to greener manufacturing processes and the use of eco-friendly materials.

The evolution of printed circuit board technology has been marked by continuous innovation and improvement. From its early beginnings to the sophisticated designs of today, PCBs have played a crucial role in advancing electronic technology. At YIC Assm, we are committed to staying at the forefront of PCB innovation, providing our clients with cutting-edge solutions that meet their specific needs.

The evolution of printed circuit board technology has been marked by continuous innovation and improvement. From its early beginnings to the sophisticated designs of today, PCBs have played a crucial role in advancing electronic technology. At YIC Assm, we are committed to staying at the forefront of PCB innovation, providing our clients with cutting-edge solutions that meet their specific needs.

Explore our PCB assembly services and discover how we can help you achieve your electronic design goals. Whether you are developing consumer electronics, medical devices, or aerospace applications, our expertise and state-of-the-art facilities ensure that you receive the best possible products and services.

For more information about our capabilities and how we can assist you, visit our PCB Assembly page.