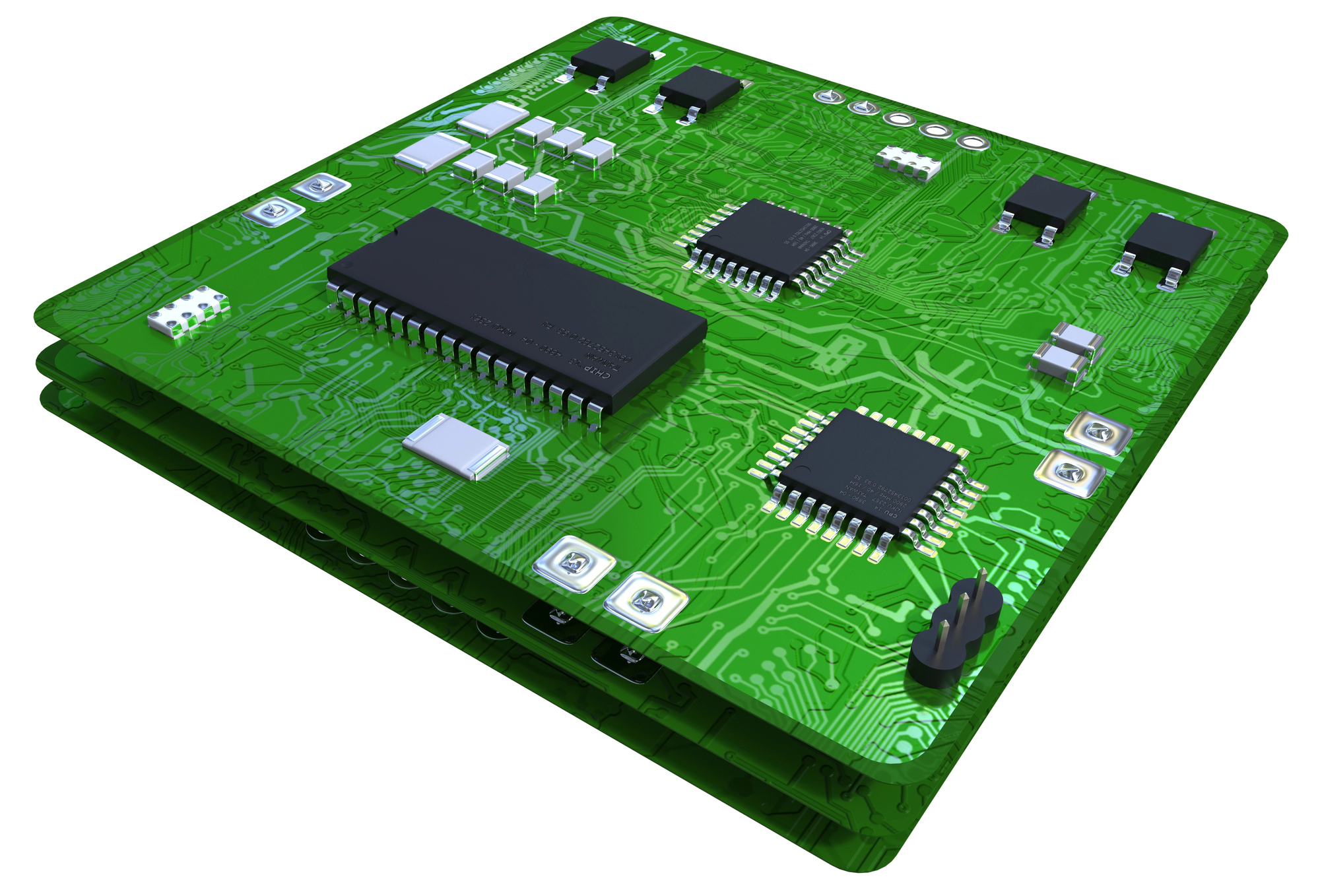

Electronic manufacturing is evolving at a rapid pace, driven by breakthroughs in automation, miniaturization, materials science, and sustainability. As we move toward 2026, these innovations are reshaping how printed circuit boards (PCBs), assemblies, and electronic systems are designed, built, and deployed. At Yun Industrial, staying ahead of these trends ensures customers receive cutting-edge manufacturing solutions that are reliable, efficient, and scalable.

Electronic manufacturing is evolving at a rapid pace, driven by breakthroughs in automation, miniaturization, materials science, and sustainability. As we move toward 2026, these innovations are reshaping how printed circuit boards (PCBs), assemblies, and electronic systems are designed, built, and deployed. At Yun Industrial, staying ahead of these trends ensures customers receive cutting-edge manufacturing solutions that are reliable, efficient, and scalable.

Smarter Automation and AI-Driven Manufacturing

Artificial intelligence and machine learning are playing a bigger role in electronic manufacturing than ever before. By 2026, AI-powered inspection systems will dominate high-precision assembly lines. These systems analyze solder joints, BGA connections, and component placement with incredible accuracy, reducing human error and improving yield rates.

Automated surface-mount technology (SMT) lines will continue to advance with faster placement speeds and smarter error detection. Yun Industrial already uses advanced automated equipment to deliver consistent quality in high-volume production—positioning the company perfectly for the next generation of smart manufacturing.

Miniaturization and High-Density PCB Designs

As consumer electronics, medical devices, and industrial systems become smaller and more powerful, the demand for high-density interconnect (HDI) PCBs and advanced BGA packaging continues to grow. By 2026, manufacturers will push even further into ultra-compact designs with tighter tolerances and multi-layer configurations.

Yun Industrial’s expertise in precision PCB assembly, BGA rework, and microelectronics gives customers a competitive edge in producing smaller, faster, and more reliable devices.

Flexible, Rigid-Flex, and Advanced Substrate Technologies

Flexible and rigid-flex PCBs are no longer niche solutions. These advanced substrates are becoming standard for applications in aerospace, medical wearables, automotive systems, and IoT devices. By 2026, flexible electronics will play a major role in next-generation sensors, smart devices, and compact control systems.

Yun Industrial continues to support customers with flexible circuit board assembly and advanced substrate solutions that meet demanding mechanical and electrical requirements.

Sustainable and Eco-Friendly Manufacturing

Sustainability is now a top priority across all areas of manufacturing. By 2026, stricter environmental regulations and customer expectations will drive even greater use of lead-free solder, conflict-free materials, and energy-efficient production processes. Manufacturers that fail to adapt will struggle to compete.

As an ISO 9001-certified electronics manufacturer, Yun Industrial is already aligned with quality, compliance, and environmentally responsible practices—ensuring long-term manufacturing stability for its customers.

Faster Prototyping and Shorter Production Cycles

Speed to market is more critical than ever. Advanced rapid prototyping, digital design verification, and fast-turn PCB assembly will continue to shrink production timelines. In 2026, customers will expect engineering feedback, prototypes, and production scaling faster than ever before.

Speed to market is more critical than ever. Advanced rapid prototyping, digital design verification, and fast-turn PCB assembly will continue to shrink production timelines. In 2026, customers will expect engineering feedback, prototypes, and production scaling faster than ever before.

Yun Industrial / ACME PCB Assembly supports this demand with flexible production volumes, prototype services, and quick-turn assembly options for startups and established brands alike.

The Future Is Being Built Now

The future of electronic manufacturing is intelligent, compact, sustainable, and fast. From AI-driven automation to flexible circuit technology and eco-conscious production, the innovations shaping 2026 are already taking hold today. Companies that invest in advanced manufacturing partnerships now will be positioned for long-term success.

At Yun Industrial, innovation is not just a goal—it’s a standard. Through advanced SMT assembly, BGA services, flexible circuit support, and full PCB manufacturing capabilities, Yun Industrial continues to help customers bring next-generation electronic products to life.

To learn more about future-ready PCB manufacturing solutions, visit

https://yic-assm.com/