In the ever-evolving world of electronics, the role of printed circuit boards (PCBs) is fundamental. They are the backbone of nearly every electronic device, from simple household appliances to complex industrial machinery. The process of PCB assembly is intricate and requires a high level of precision and expertise. One of the most crucial aspects that ensure the reliability and functionality of these PCBs is quality control. At Yun Industrial, we understand that meticulous attention to detail during the PCB assembly process is not just a requirement but a commitment to delivering excellence.

PCB Assembly and Quality Control: A Symbiotic Relationship

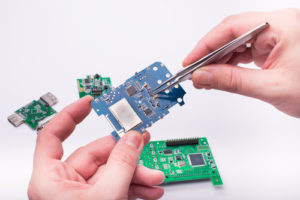

PCB assembly involves several steps, including component placement, soldering, inspection, and testing. Each stage must be meticulously executed to ensure that the final product meets the required specifications and standards. Quality control in PCB assembly is not a one-time task but a continuous process that begins with the design phase and extends through to the final inspection.

PCB assembly involves several steps, including component placement, soldering, inspection, and testing. Each stage must be meticulously executed to ensure that the final product meets the required specifications and standards. Quality control in PCB assembly is not a one-time task but a continuous process that begins with the design phase and extends through to the final inspection.

Quality control measures in PCB assembly involve rigorous testing protocols to detect any potential issues early in the production process. This can range from automated optical inspection (AOI) systems, which use cameras to check for defects in solder joints, to in-circuit testing (ICT) that verifies the electrical performance of the assembled PCB. At Yun Industrial, we employ advanced testing equipment and highly trained professionals to ensure that every PCB assembly meets the highest standards of quality and reliability.

The Role of Quality Control in Reducing Failures

The significance of quality control in PCB assembly cannot be overstated. Without stringent quality control measures, there is a risk of producing PCBs with defects that could lead to device malfunctions or failures. In critical applications such as medical devices, automotive systems, and aerospace equipment, even the smallest defect in a PCB can have catastrophic consequences. This is why Yun Industrial places a strong emphasis on quality control throughout the PCB assembly process.

By implementing rigorous quality control standards, we can reduce the likelihood of failures and extend the lifespan of electronic devices. Quality control ensures that the PCBs are not only functional but also durable, capable of withstanding the rigors of their intended applications. This commitment to quality is why many industries trust Yun Industrial for their PCB assembly needs.

Enhancing Performance and Reliability through Quality Control

Quality control in PCB assembly is not just about preventing defects; it is also about enhancing the overall performance and reliability of the electronic device. A PCB that has been assembled with a focus on quality will exhibit superior electrical performance, better thermal management, and increased mechanical stability. These factors are crucial in ensuring that the device operates efficiently under various conditions.

At Yun Industrial, we believe that quality control is integral to the performance of the final product. Our team of experts works diligently to ensure that each PCB assembly meets the stringent quality requirements of our clients. By adhering to international quality standards and employing state-of-the-art equipment, we can deliver PCB assemblies that consistently meet and exceed customer expectations.

Building Trust through Quality Control

In the competitive world of electronics manufacturing, building trust with clients is essential. Quality control plays a vital role in this regard by ensuring that the products we deliver are reliable and free from defects. At Yun Industrial, we have built our reputation on a foundation of quality and reliability. We understand that our clients depend on us to provide PCB assemblies that are not only high-performing but also safe and durable.

In the competitive world of electronics manufacturing, building trust with clients is essential. Quality control plays a vital role in this regard by ensuring that the products we deliver are reliable and free from defects. At Yun Industrial, we have built our reputation on a foundation of quality and reliability. We understand that our clients depend on us to provide PCB assemblies that are not only high-performing but also safe and durable.

Our commitment to quality control extends beyond the assembly process. We continuously invest in the latest technologies and training programs to keep our team at the forefront of industry standards. This dedication to excellence allows us to maintain the trust of our clients and establish long-term partnerships based on mutual respect and reliability.

Quality control is a cornerstone of PCB assembly, ensuring that each board is produced to the highest standards of excellence. At Yun Industrial, we are committed to maintaining rigorous quality control measures to deliver reliable and high-performance PCB assemblies. By prioritizing quality at every stage of the process, we ensure that our clients receive products that meet their exacting requirements, helping them to succeed in their respective industries.

By choosing Yun Industrial for your PCB assembly needs, you are partnering with a company that values quality and precision above all else. Visit our website to learn more about our commitment to quality control and how we can support your next project.