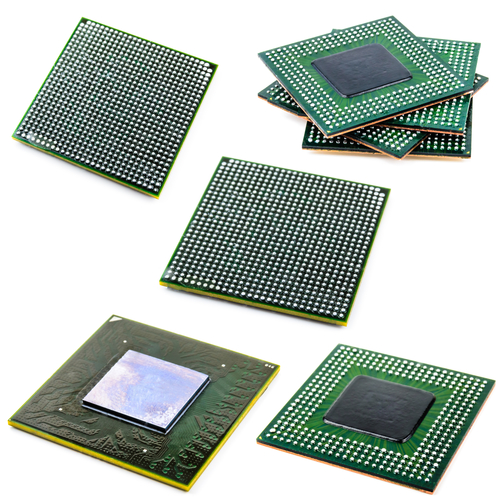

BGA Assembly (Ball Grid Array Assembly) plays a critical role in modern electronics manufacturing, offering a reliable and efficient way to mount integrated circuits onto printed circuit boards (PCBs). As electronic devices continue to shrink in size while increasing in functionality, the demand for compact and high-performance components has driven the widespread adoption of Ball Grid Array assembly.

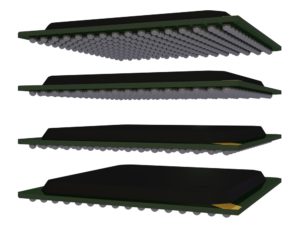

Unlike traditional through-hole or surface-mount technology (SMT) components, BGA assembly utilizes an array of solder balls on the underside of a package to create connections with the PCB. This design allows for more interconnects in a smaller space, improving electrical performance and heat dissipation. The result is increased reliability and enhanced signal integrity—essential for applications such as consumer electronics, automotive systems, medical devices, and telecommunications equipment.

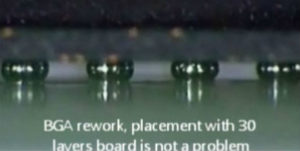

The BGA assembly process involves precise solder paste application, accurate component placement, and controlled reflow soldering to ensure strong and consistent connections. Automated inspection methods, such as X-ray and optical inspection, are crucial to detecting defects like misalignment, voids, or solder joint failures that could compromise the final product’s performance.

The BGA assembly process involves precise solder paste application, accurate component placement, and controlled reflow soldering to ensure strong and consistent connections. Automated inspection methods, such as X-ray and optical inspection, are crucial to detecting defects like misalignment, voids, or solder joint failures that could compromise the final product’s performance.

One of the key advantages of Ball Grid Array assembly is its ability to support high-density packaging while minimizing issues like solder bridging and short circuits. Additionally, BGA components offer improved thermal performance by efficiently conducting heat away from the chip, making them ideal for high-power applications.

At YIC-ASSM, advanced manufacturing techniques and rigorous quality control ensure top-tier BGA assembly solutions tailored to industry needs. Whether for aerospace, industrial automation, or cutting-edge consumer devices, YIC-ASSM provides precision-engineered PCB assembly services that meet the highest standards of reliability and performance.

Yun Industrial / ACME PCB began offering Ball Grid Array (BGA) Assembly services in 1994. Over these many year’s experience BGA assembly with X Ray inspection machine, right assembly procedure, we are very confident to say that we know, and we can build a high quality, good yield rate BGA assembly board.

Yun Industrial / ACME PCB began offering Ball Grid Array (BGA) Assembly services in 1994. Over these many year’s experience BGA assembly with X Ray inspection machine, right assembly procedure, we are very confident to say that we know, and we can build a high quality, good yield rate BGA assembly board.

For expert BGA assembly solutions, visit YIC-ASSM today!