What Do You Actually Need to Make a Printed Circuit Board?

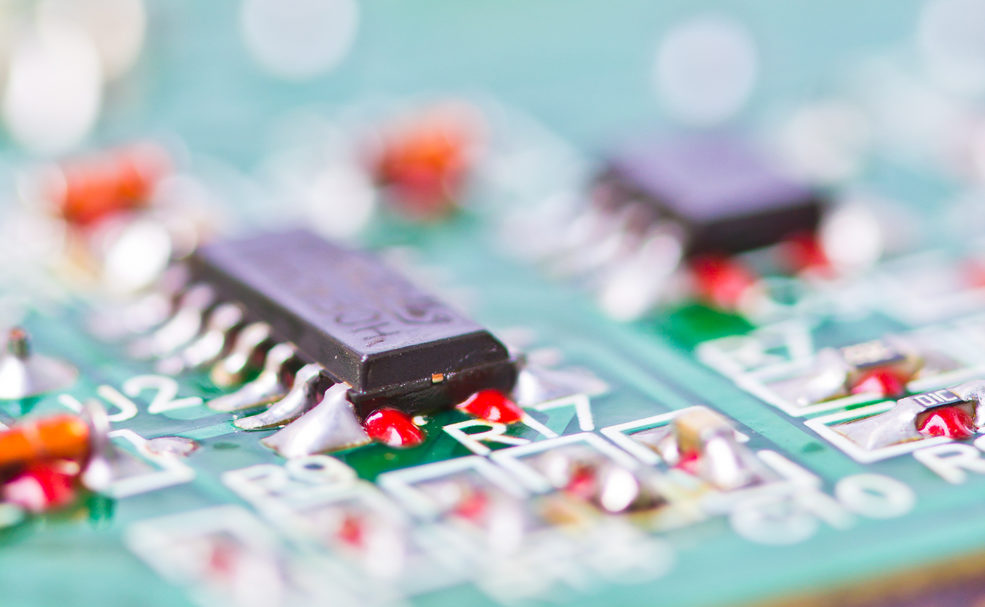

Printed circuit boards (PCBs) are the backbone of nearly every electronic device in today’s world. If it has computing power—whether it’s a medical device, automotive module, smartphone, industrial controller, appliance, or aerospace system—it relies on a PCB to function. But what does it really take to make a PCB, and what goes into assembling one that performs reliably? While the completed product looks simple, the process behind it is a precise blend of engineering, materials, and manufacturing expertise.

Starting With the PCB Itself

Every project begins with the PCB substrate—the base material that provides structural support and houses the electrical pathways. These pathways are typically made from copper and etched into multiple layers depending on the complexity of the design. Yun Industrial ACME PCB Assembly works with single-layer, double-layer, and multilayer board designs to support industries requiring increasingly compact and powerful electronics.

The board alone, however, cannot function until it is assembled. That’s where the real craftsmanship begins.

Essential Components Needed for PCB Assembly

To bring a PCB to life, you need a wide range of electronic components such as:

Resistors

Capacitors

Diodes

Integrated circuits (ICs)

Transistors

Connectors

Microcontrollers

Sensors and specialty components

These components are selected according to the design and the performance requirements of the device. High-quality sourcing is essential, which is why Yun Industrial’s purchasing and engineering teams work closely with vetted suppliers to ensure every part meets strict standards.

Soldering Materials and Equipment

Once the components are ready, the next requirement is soldering—a critical part of PCB assembly. Soldering secures components to the board and ensures reliable electrical connections.

Common soldering materials include:

Solder wire

Solder paste

Solder bars

Solder preforms

Flux to improve adhesion and remove oxidation

Soldering equipment ranges from manual solder stations for delicate work to automated SMT pick-and-place machines, reflow ovens, wave soldering systems, and inspection tools. At Yun Industrial ACME PCB Assembly, advanced automated processes ensure consistent quality across small-batch prototyping and high-volume production runs.

Skilled PCB Assemblers and Advanced Processes

While materials and tools are essential, skilled technicians and engineers are the true heart of PCB manufacturing. They verify designs, inspect solder joints, test assembled boards, and ensure that every PCB meets rigorous performance and safety standards.

Of course, there’s far more to PCB manufacturing than what meets the eye. Yun Industrial specializes in turnkey PCB assembly—covering everything from design support and prototyping to full-volume production, testing, and quality control.

If you’re looking for a trusted, experienced, and fully capable PCB assembly partner, Yun Industrial ACME PCB Assembly is ready to help. Contact us today to discuss your project needs.

Using the soldering equipment, printed circuit board assemblers, like Yun Industrial Acme PCB Assembly, solder on the electronic components. The soldering equipment includes things like solder wire, solder paste, solder bar, and solder performs.

Of course, there’s a lot more to printed circuit board assembly, but we’re not about to give away all of our secrets! If you want to work with a trusted and experienced printed circuit board assembler, contact us today!