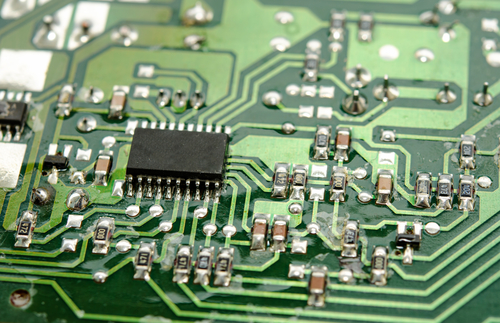

Just as every home requires a strong foundation, every Printed Circuit Board (PCB) relies on a sturdy base called a substrate. The substrate is the physical material that supports all electrical components and copper traces on a circuit board. Without it, a PCB would lack structure, reliability, and functionality. Choosing the right substrate is one of the most critical steps in the design and manufacturing process.

Why the Substrate Matters

The PCB substrate serves multiple purposes—it provides mechanical support, electrical insulation, and thermal stability for the board. It acts as the canvas upon which the entire electronic design is built. The type of substrate material used can significantly influence how a circuit board performs in real-world applications.

For instance:

Rigid substrates offer strength, stability, and dimensional accuracy, making them ideal for industrial and high-performance electronics.

Flexible substrates provide adaptability and space efficiency, allowing PCBs to bend or fold within compact devices such as smartphones and medical equipment.

A well-chosen substrate ensures the PCB can withstand heat, vibration, and environmental stress while maintaining consistent electrical performance.

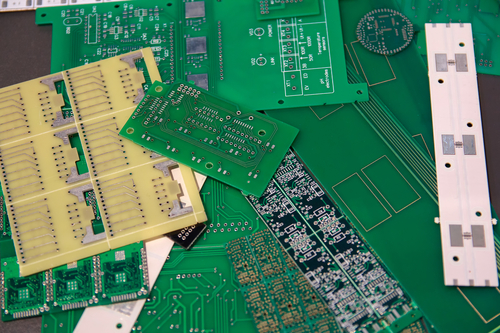

Common PCB Substrate Materials

As technology advances, PCB manufacturers use a wide range of materials tailored to different performance and environmental needs:

FR-4 (Fiberglass Epoxy Laminate): The most common substrate, made of woven fiberglass cloth and epoxy resin. It’s known for its strength, flame resistance, and cost-effectiveness.

Polyimide: A flexible, heat-resistant polymer used in flexible and rigid-flex PCBs. It’s ideal for high-temperature and high-density applications.

PTFE (Teflon): Used in high-frequency or microwave PCBs due to its excellent dielectric properties and low signal loss.

Metal-Core Substrates: Used in LED lighting and power electronics, offering superior heat dissipation for high-current applications.

Each substrate type offers unique properties that affect the PCB’s thermal management, signal integrity, and durability.

Partner with ACME PCB Assembly

At Yun Industrial / ACME PCB Assembly, we specialize in manufacturing PCBs with precision and expertise—using the right substrate materials for your project’s specific performance requirements. Whether you need rigid, flexible, or hybrid PCB solutions, our team ensures the best results in quality, reliability, and cost efficiency.

Contact ACME PCB Assembly today to learn more about substrate selection and how it impacts your PCB’s performance and longevity.