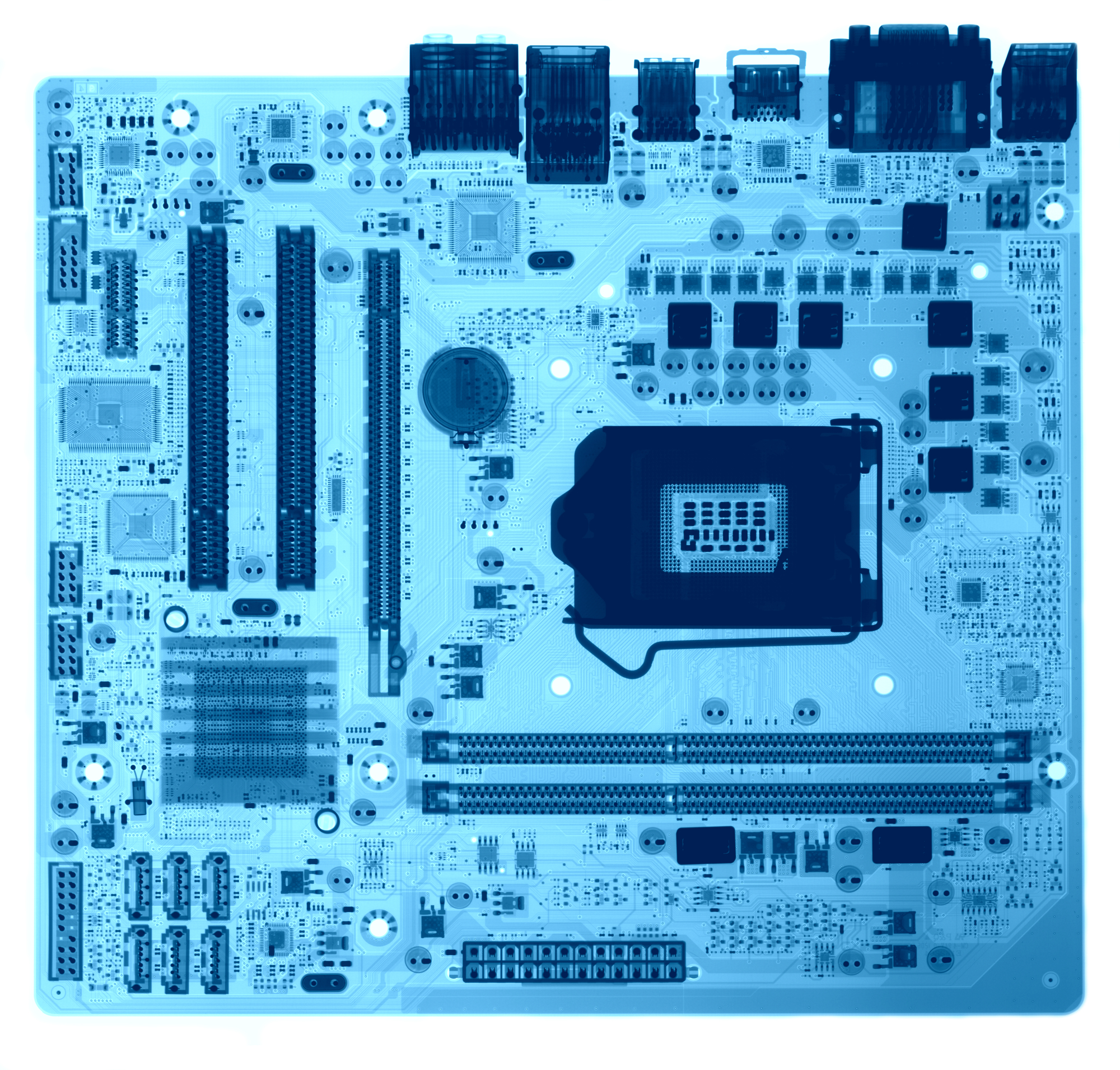

Yun Industrial Acme Printed Circuit boards offers the top-quality and technology in the manufacturing and testing of printed circuit board assembly. We also X-ray inspect all of our products, this technique is widely used in PCB assembly in order to maintain excellent quality in their products.

Automated X-ray inspection (AXI) is a technology based on the same principles as automated optical inspection (AOI). It uses X-rays as its source, instead of visible light, to automatically inspect features, which are typically hidden from view.

Automated X-ray inspection (AXI) is a technology based on the same principles as automated optical inspection (AOI). It uses X-rays as its source, instead of visible light, to automatically inspect features, which are typically hidden from view.

X-ray inspection is widely used in lots of applications such as medical, industrial control, and aerospace for control the quality of board assemblies and to analyze defects of hidden solder joints. X-ray has a unique advantage that is materials absorb X-rays proportional to their atomic weight and all materials absorb the X-ray radiation differently depending on their density, atomic number and thickness. Generally speaking, materials made of heavier elements absorb more X-rays and are easily imaged, while materials made of lighter elements are more transparent to X-rays. For optimal use of this tool both the right equipment along with a properly-trained staff, which can properly interpret the results and their relationship to process and component variables, should be used.

Skilled XRAY technicians like those at Yun Industrial Acme Printed Circuit boards make a difference in being able to help you detect process problems or screen for known defects. For instance, some defects such as bridges can be “seen” directly while others can only be detected by their signatures. The correspondence of the signatures to the various defects is known from experience, but can be understood from simple geometrical considerations. For example, if a single BGA solder joint appears brighter than its neighbors, it is obviously not as thick and, hence, must be open (not properly soldered). Yun Industrial Acme Printed Circuit boards skilled X-ray technicians can help you screen for defective products based upon your developed acceptance criteria for the given defect.

We provide a complete suite of PCB services, including PCB Assembly, Rework and Modification, BGA, SMT, Turnkey, Thru-Hole, Lead Free, and Prototype Assembly, plus an extensive line of Add on services.

We are a mid-sized EMS company – a good match for production runs that range from prototype to 20,000 units. Being a mid-sized contract manufacturer, we are more flexible and responsive to production requirements than the larger assembly houses.

We continually strive to have the latest technology to provide the highest quality PCB assembly services with competitive prices.