WHAT IS LOW PRESSURE MOLDING?

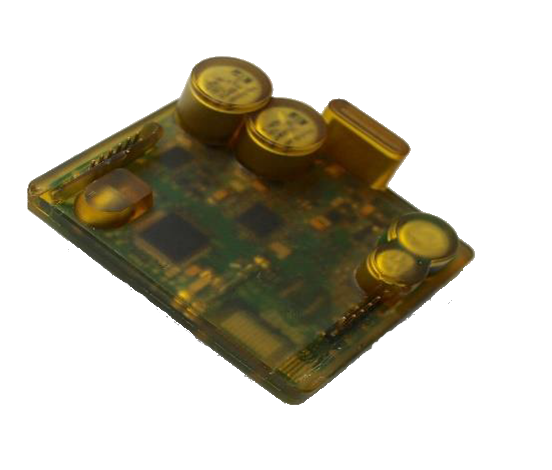

Low pressure molding is a one-step process that encapsulates, and seals to protect electronics. By using a simple mold set allows for the process to use a lot less material than the traditional potting and eliminate the housing.

Low pressure molding is a one-step process that encapsulates, and seals to protect electronics. By using a simple mold set allows for the process to use a lot less material than the traditional potting and eliminate the housing.The whole process is pretty fast – producing the finished part in seconds. This unique technology is primarily used for encapsulating or over molding of electronic assemblies, including battery packs, PCBA, micro-switches, solenoids, sensors, connectors and wire harnesses.

Some additional benefits to this technology are environmental protection from moisture and vibration, low cost delicate assemblies can be processed, no secondary curing and is environmentally friendly.

Eliminates the need for housing, which is a great cost-saving solution because it reduces capital investment costs, and it provides quick cycle times and protects fragile components.

Wire Harness Strain Relief

Low Pressure Molding is the chosen method to protect delicate fine-pitch connector assemblies. It also can provide strain relief within the same application. The process is flexible and requires low capital investment.

Low Pressure Molding provides environmental protection from dust, moisture and vibration, and adheres to LED lenses. Molding can be done with the LED lens exposed or completely encapsulated.

Molding switches can be challenging because of the small size and thin, delicate side walls. Low Pressure Molding reduces complexity by removing the two-component thermoset curing process.

Low Pressure Molding reduces failure rates compared to traditional potting, particularly critical in the mobile phone battery industry.

Low Pressure Molding offers huge benefits to the connector industry because of the low molding pressures.

Yun Industrial and ACME PCB Assembly has been providing Electronic Manufacturing Services (EMS) and Printed Circuit Board (PCB) assembly for 26 years.