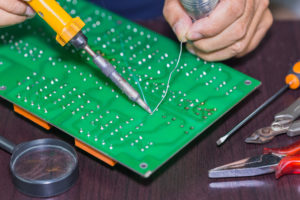

Before the 1960s, through-hole assembly was the only method available for mounting components onto printed circuit boards (PCBs). The process was labor-intensive and required drilling holes through the board, but it was the foundation of modern electronics.

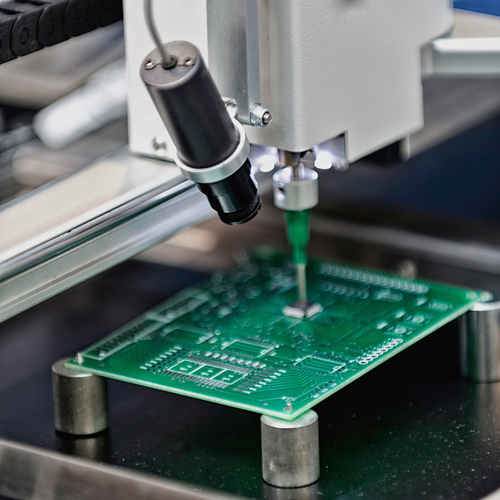

Then came surface mount technology (SMT)—a revolutionary method that allowed for components to be mounted directly onto the surface of a PCB without drilling. SMT components are smaller, more compact, and can be mounted on both sides of the board, resulting in more efficient, high-performance designs.

So, with all of SMT’s advantages, why hasn’t through-hole technology disappeared? Because in some cases, through-hole assembly still outperforms SMT.

When Through-Hole Outperforms SMT

When Through-Hole Outperforms SMT

Through-hole PCBs may take up more space, but they come with one key benefit: superior mechanical strength. Components mounted using through-hole assembly form stronger connections between the component leads and PCB layers, making them more resilient under stress.

Rugged Applications: Military, Aerospace, and Beyond

In industries like military, aerospace, and industrial equipment, electronics must withstand extreme temperatures, shock, vibration, and acceleration. Through-hole technology offers the durability and long-term reliability needed in these demanding environments.

That’s why you’ll still find through-hole PCBs in:

Missile guidance systems

Satellite electronics

Avionics and aircraft controls

Heavy-duty industrial machinery

These are not places where you want your connections to fail.

Through-Hole in Prototyping

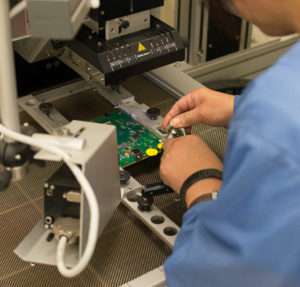

Through-hole is also widely used in prototyping and R&D. During development, designers often need to quickly swap out components or troubleshoot circuits.

With through-hole components:

Swapping and testing is easier

Hand soldering is more manageable

Circuit revisions are quicker

This flexibility makes through-hole mounting a preferred choice for engineering teams building and refining prototypes.

Choose a Vendor That Offers Both

When choosing a PCB assembly partner, it’s important to work with a vendor skilled in both surface mount (SMT) and through-hole assembly. This gives you more options and the flexibility to match the right assembly method to the needs of your application.

At Yun Industrial ACME PCB Assembly, we offer:

Full-service SMT and through-hole PCB assembly

Rapid prototyping and small-batch production

Reliable manufacturing for rugged and specialized electronics

Whether you’re building the next generation of smart devices or aerospace technology that must perform under pressure, we deliver quality, performance, and precision.

Get in Touch Today

Ready to bring your next project to life with the right PCB assembly method?

Contact Yun Industrial ACME PCB Assembly to explore your options and get a custom quote.

When Through-Hole Outperforms SMT

When Through-Hole Outperforms SMT